COMPANY

HISTORY

In 1928 a wood process production unit was founded by Pantelis Sinos in Naoussa. The unit produced Vienna Type wooden chairs until 1936 when the company decided to turn over a new leaf by producing wooden crates intended for Greece’s domestic market.

In 1953 his son, Stefanos Sinos, took over the business and started to manufacture light fruit – crates designed for exportation, in a time when Greek fruit exporting was starting to flourish. The company’s orientation changed by creating a single-use fruit crate, thus assisting its export needs.

In 1971 the board decided for the company’s further expansion in the fruit crate business and therefore the factory was relocated to its current position in Anthemia (district of Kopanos), in a privately – owned 7-acre site and premises that round to 1.000 sq. m. The history of wooden fruit crate production in Greece experienced a transformation, as a variety of innovations and new production methods were being introduced by Sinos S.A. Production lines were updated and production capacity rose sharply.

Nowadays, Pantelis and Ilias Sinos, the third generation, are in charge of the company. They carry on its longtime history by introducing new ideas and innovations, expanding its operations to foreign customers and maintaining meanwhile its family profile and culture. The building facilities amount to 14,000 sq. m., within a plot of 70 acres and the company engages approximately 55 employees. There are 3 fruit – crate manufacturing lines, capable of producing 15,000,000 crates per year and one pallet making line, which produces about 150,000 pallets annually. Through a modernly equipped fleet of means of transport, with a view to safer product traffic and a distribution network capable of meeting needs both in Greece and abroad, Sinos S.A. remains a pioneer in the field of wooden fruit crates.

TECHNOLOGY

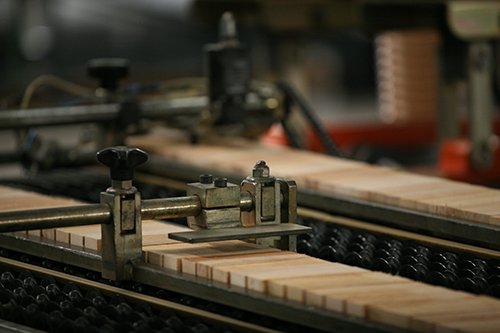

Sinos S.A. has 3 state-of-the-art production lines, with a capacity of about 15,000,000 crates per year, which are able to cover any service need. Through production quality assurance systems, a continuous control of the box is carried out in order for it to arrive safely and in the right condition to the customer. The two stamping machine lines cover production needs by stamping approximately 140,000 crates per day, using state-of-the-art cutting-edge technology for both wooden boxes and Hardboard products through the use of UV polish.

Equipped with the required technology to remove harmful substances and fungi from wood, mainly in the manufacture of pallets, our company continues to innovate, thus contributing to the protection of the products and faithfully observing the regulations regarding the fruit export activities. Our means of transport have been equipped with the technology of folding ceilings, according to which the roof converges and keeps the boxes in place for safer handling and for ensuring their quality.

ENVIRONMENTAL RESPONSIBILITY

The company’s raw materials come from trees that are planted with the purpose of being cut and used for the manufacture of wooden crates and pallets. Consequently, the environment is not thoughtlessly weighed down through tree felling in unauthorized forest areas.

Production residues are recycled and used from external partners in order to produce other products.

The wooden crate is proven to be the most environmentally friendly as opposed to other packaging materials. From the manufacturing period to the use stage, it not only does not strain nature but it also has additional antibacterial capabilities, that discourage the growth of micro-organisms which affect the fruit quality.